Emergency Mobile Machining and Installation

We are equipped to respond fast with emergency mobile machining services, helping vessels recover from unexpected damage with minimal delay.

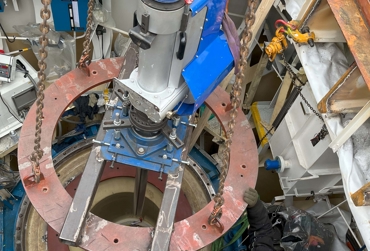

We bring our machining capabilities directly to the vessel. Our mobile units are equipped with certified tools and specialized equipment, enabling us to perform precision machining and mechanical repairs on-site. Whether it’s stern tube boring, thruster housing alignment, or shaft journal machining, we perform class-approved work that meets tight tolerances, anywhere in the world.

Many of our projects combine workshop-based overhauls with onboard installation and final alignment. From complete shaft line packages to individual components, we manage the entire process, from dismantling and transport to reinstallation, alignment, and documentation.