Laser Cladding - Fast and Cost-Effective

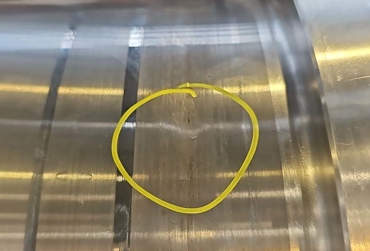

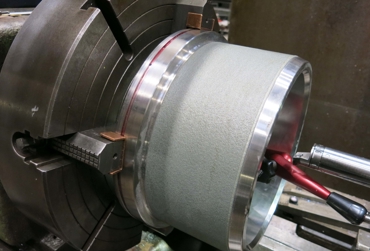

Breakdowns, wear, and corrosion can severely damage critical marine parts. With our class-approved laser cladding process, many of these components can be fully restored.

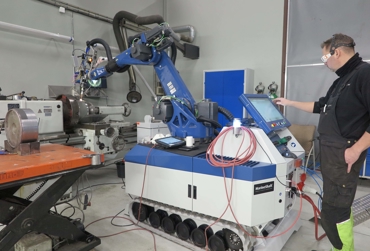

We have used this technique for years at our urgent repair workshop. Today, our expanded laser cladding capacity and robotic equipment offer faster turnaround and enhanced repair options for a wide range of shaft line and propulsion components.